Artificial Intelligence

How Artificial Intelligence is Revolutionizing Logistics:

Discover how warehouse automation AI is reshaping logistics by improving efficiency, accuracy, and cost savings. This guide explains the technologies driving AI in warehouses and how businesses can leverage it to stay ahead.

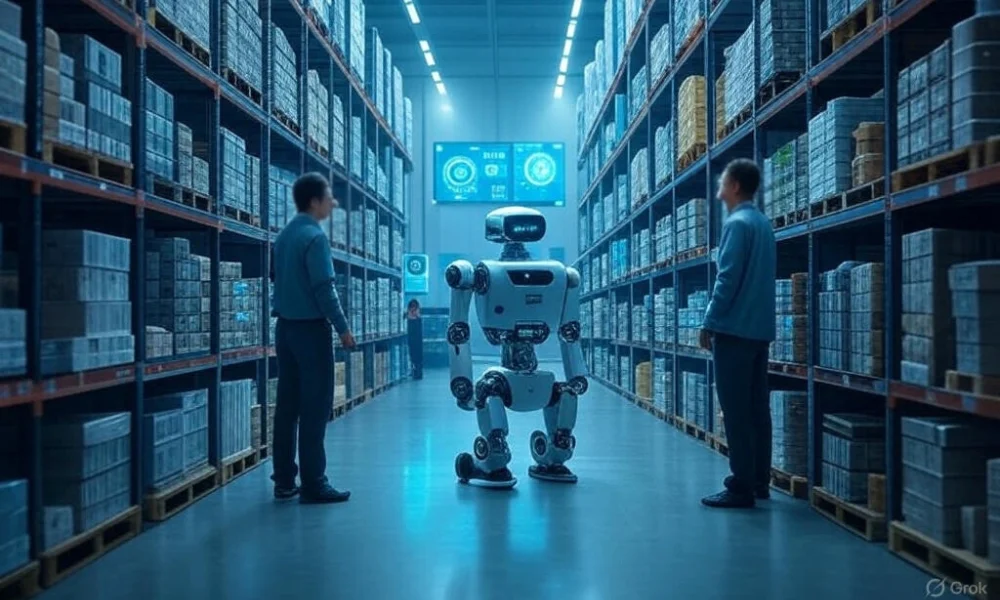

Imagine a warehouse full of robots, which zoom around racks, while AI calculates product demand even before I could think about it. I have seen how the workers and machines can now work together like teammates, not competitors. This new epoch of warehouse automation AI is no longer a dream of the future; it is happening and it’s changing everything.

Definition:

Warehouse automation artificial intelligence is a system that uses artificial intelligence and smart machines to automate storage, picking, packing, and tracking of inventories in warehouses.

I’ve learned that warehouse automation AI is the tool that helps me minimize the human errors, speed up the shipping and cut my operating costs by a large margin. It provides me with control over complex logistics without a need to hire additional people. AI technologies such as robotics, machine learning, and real time processing of data already facilitate the warehouse tasks becoming faster and more accurate.

In this blog post I’ll take you through how AI is reinventing warehouses like mine and the AI tools that are leading this huge revolution. I will also tell you why it is necessary for those who deal with running a logistics business or operating a warehouse nowadays with high-speed market dynamics in sight.

What is Warehouse Automation AI?

- I have realized that when it comes to warehouse automation AI, it is not just some cool machines or software. It is smarter way of running my entire warehouse. That system relies on the artificial intelligence to automate everything from inventory organization to packing the shipments. It assists me to increase efficiency but without making operations complicated and complex.

- Conventional automation system executes repetitive tasks with a cycle-preprogrammed machine. However, AI extends to do that and learns and adjusts to changing warehouse needs as time goes by. In other words, I get smarter systems that will scale with my business as opposed to just taking orders.

- Warehouse automation AI relies on integrating robotics, sensors, machine learning and real-time data. It is able to automatically direct orders, monitor stock and even warn me before an item goes out of stock. This improves the accuracy of my daily work, as well as makes it quicker and less stressful.

Which of the Technologies Are Driving Warehouse Automation AI?

- Once I began using the warehouse automation AI, I immediately understood that it was not some particular tool, it is a set of smart technologies. These systems merge in effect, to simplify my tasks and control my whole operation in real time.

- However, one of the most important game changers is computer vision. It enables machines to see and recognise items, scan barcodes, and monitor the shelves. I do not think of lost items and incorrect counts anymore , the latter is managed visually by AI-powered cameras.

- Machine learning makes my system learn the patterns over time. It is able to predict the items that are likely to be highly demanded and where I should put them for easier access. It seems that the system anticipates me even before I ask for it.

- Robotics is not behind also. I utilize autonomous mobile robots (AMRs) which help in shifting goods from one place to the other without human assistance. These robots are in continuous operation as they automatically avoid obstacles and route optimizations.

- Natural language processing enables the workers such as me to talk with systems by voice command. I can order an inventory update or pick list without having to touch the screen. It is more efficient and so much safer working on a busy shift.

- IoT devices interconnect all the parts of the warehouse. They monitor inventory, temperature, and machine health in the process. With the collaboration of IoT and AI, I have updates even before an issue arises.

What are the Benefits That My Business will Receive From a Warehouse Automation AI?

- I have experienced personally the impact of automation AI in the managing of daily tasks in warehouses. First thing that I noticed was how everything was much faster. Orders are picked and packed in minutes, not in hours. This pace is useful in satisfying the customer expectation and keeping me competitive.

- Another advantage that I love is cost reduction. I require less of manual work and overtime shifts. AI enabled systems eliminate waste, and eliminate costly mistakes, which puts more money in my pocket each month. It also assists me to keep a record of all the items to avoid losing or misplacing any of them.

- Scalability is a great issue for my growing business. When the demand rises, AI systems change automatically. I can have more orders without employing more workers or increasing room. That flexibility makes me confident at peak seasons.

- AI enhances accuracy and quality as well. It makes fewer errors than the mankind and identifies the problem, which by myself I would not notice. It will lead to less returns and satisfied customers.

- Safety is one of the most valuable aspects for me. AI is useful in helping me to track workspaces and warn me of the dangers. It even helps to maintain clear paths for both people and machines.

Companies Which Are Implementing Warehouse Automation AI Nowadays?

- When I began researching the warehouse automation AI, I did some research on what big companies had already been doing. That brought me to the awareness of reality impact and taught me the ideas to improve my own operations.

- Amazon is one of the most widely known of such cases. They employ thousands of robots throughout their warehouses to transport and support the work of human workers. Their AI estimates inventory requirements and directs packages more quickly than any human setup I’ve looked at.

- Walmart has also embarked on the use of AI in a big way. They use it in the prediction of demand that is demand forecasting, in the management of inventory and in automatic restocking. This equips them with having full shelves to avoid and lead ahead in customer needs without wasting space.

- One of the most forward-looking work in this space is being done by Ocado, a UK-based online grocer. They have created smart warehouses with robots that pick their groceries at speed and with accuracy. Their system relies on AI to monitor all the orders in real time and that is what I would like to have for my business.

- Even, the small companies are joining in. A wide range of the U.S. businesses is adopting SaaS-based AI tools that do not require enormous investments. These systems aid in smart picking, storage planning and up to date updates , ideal for warehouses such as mine.

What are The Challenges that I Should Anticipate in Warehouse Automation Ai?

- I assumed that it would be easy to use warehouse automation AI before I started using it. However, I soon learned that there are real challenges that I had to face. The initial cost was one of the biggest. No-one is going to want to spend a fortune on smart google AI robots, sensors, and AI software. I had to plan well so that my investment should bear fruit in the long term.

- Other obstacle was to Integrate with my existing systems. I was already on a basic warehouse management system and I had to sync this with AI tools and this time consuming. I required help on plugging in my data correctly and training my staff on how to handle the new interface.

- I also had to consider the effect of the workforce. Some employees had certain kinds of fears about AI taking their jobs. I ensured that I reskill them and get them involved in the transition. That brought them to the realization that the AI was a form of tool rather than threat.

- Cybersecurity became a concern too. With everything being connected, inventory to delivery routes, I had to secure my data and be secure against breaches. Faith in AI is the faith in the data, and I had to make it sure it remained accurate and confidential.

How does the future of warehouse automation look like AI?

- If I imagine what the future warehouse automation AI holds, I see warehouses that run almost by themselves. Systems will become smarter and self-governing, and will be able to make decisions straight away without waiting for my opinion. I see the fully autonomous warehouses as common, especially for those who wish to have speed and consistency.

- I’m also excited for the prospect of AI and blockchain collaboration. This can provide me complete visibility to each item, supplier to shipping. I would be able to track everything with full transparency and no mistake. Such trust and traceability would make my supply chain a step further.

- Sustainability will also increase with AI. Smart systems will help to cut waste and minimise energy consumption for planning greener delivery routes. In my opinion, eco friendly warehouses will become a strong selling point for such companies as mine that desire the environment.

- One more enormous paradigm shift will be mass customization. AI will help me achieve personalized orders that do not compromise the speed at which they are made. That’s the sort of service that customers now expect, but it is made possible by automation AI.

Steps to Take in Order To Start Using the Warehouse Automation AI Nowadays:

- First time I heard about warehouse automation AI, I assumed that it would be intimidating. However, I learnt that little beginnings made everything simple. The first step that I took was evaluating my operations. I examined where I was wasting time or errors particularly while picking, and inventory counts.

- Then, I defined my goals for automation. I didn’t attempt to change everything at one go. I concentrated on the picking errors reduction and order speed improvement. That provided me with a map and kept me on the track in the course of the transition.

- I also selected scalable tools that can work within my existing setup and be able to grow my business. I began by implementing cloud-based software and basic robots that did not require the whole overhaul of the system. This way I did not have to make large upfront outlay to see the results.

- My training of my team was equally important. I ensured everybody was taught on how to work with the new tools and not against them. I conducted brief training sessions and responded to their queries in the actual time. It smoothened it and increased team confidence.

- Lastly, I introduced a pilot program on one of the zones at my warehouse. That allowed me to try out the AI tools without wrecking everything. After it worked beautifully, I diversified to other areas. It is a walk through process, and now I am in command of it.

Conclusion:

As I’ve found out, warehouse automation AI is not the latest trend, it is the future of logistics. It is revolutionizing how I manage my warehouse from the speeding up of process to the savings I make by the cost cutting and the increased accuracy. Big players no longer have a monopoly on the technologies that drive automations such as robotics, machine learning and computer vision. They are open for companies of any size.

Benefits are clear: improved efficiency, better accuracy and scalability. But there are the challenges and its costs, and workforce changes. If you do it step by step, determine where you want to go and train your crew, the process will not be so hard. And with the right tools, businesses can grow and be competitive in an ever-changing market.

If you were thinking of using AI in your warehouse it’s about time that you take that first step forward. From automated picking to real time inventories, AI can help. The warehousing of tomorrow is smarter, faster, and better connected. Are you going to be a part of it?

-

Artificial Intelligence8 months ago

Artificial Intelligence8 months agoHow to Use Grok AI: A Complete Guide

-

Artificial Intelligence10 months ago

Artificial Intelligence10 months agoWhat is Artificial Intelligence? A Comprehensive Guide for Businesses and Enthusiasts

-

Artificial Intelligence9 months ago

Artificial Intelligence9 months agoUnlocking the Power of Artificial Intelligence Tools

-

Artificial Intelligence9 months ago

Artificial Intelligence9 months agoWhat is DeepSeek? Revolutionizing AI with Cutting-Edge Solutions

-

Artificial Intelligence5 months ago

Artificial Intelligence5 months agoAI Technologies in Warehouse Automation:

-

Artificial Intelligence5 months ago

Artificial Intelligence5 months agoPredictive Analytics for Demand Forecasting:

-

Artificial Intelligence6 months ago

Artificial Intelligence6 months agoMeta’s AI Push: The Standalone Assistant App Set to Rival ChatGPT

-

Artificial Intelligence8 months ago

Artificial Intelligence8 months agoWhat is Grok AI? A Game-Changing Chatbot with Real-Time Insights